How to use the Modela: Difference between revisions

No edit summary |

change in catagories |

||

| (23 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

[[Image:Modela.jpg|thumb|300px|right|Roland Modela can be used to mill circuit boards.]] | [[Image:Modela.jpg|thumb|300px|right|Roland Modela can be used to mill circuit boards.]] | ||

== Step by | === Step by Step === | ||

--- | |||

[[Image:Modela_buttons.jpg|thumb|200px|right|Modela buttons, from top: Power, View, Up, Down]] | [[Image:Modela_buttons.jpg|thumb|200px|right|Modela buttons, from top: Power, View, Up, Down]] | ||

# Design the circuit board | # Design the circuit board or select and download a cad file from the hello-world circuits section on the http://fab.cba.mit.edu/about/fab/ or from [[hello world electronics]] | ||

# Stick a piece of PCB stock onto the cutting plane | # Stick a piece of the PCB copper plated stock onto the cutting plane at the 1,1 inch intersection on the grid. | ||

# Open | # Open fab [[Fab modules]] software by writing fab the terminal | ||

# Click input and get a | # Click input and get the design file (.cad file) or a pre-designed png file. | ||

=== Make the toolpath and mill a circuit === | |||

# Open [[Fab modules]] in a Linux Terminal by writing | |||

fab | |||

or click on the shortcut launcher in desktop. | |||

#Selct from format: design.cad to process, Roland Modela .rml and then click make_cad_rml | |||

#Click Load cad, select the right file.cad | |||

#Select mill traces (1/64) | |||

#Go to the text area and uncomment the "#" and remove the "#" in front of output="traces" (* The "#" symbol is a comment, which will ignore the line of the command after the sign. | |||

) | |||

#click on make_png | |||

#change the offset to 8 | |||

# On the Modela go to "view mode" by pressing on the view button on the Modela | |||

##Press view on the Modela machine | |||

# Tape down copper board with double tape | |||

# Put 1/64 inches bit in the modela, which is 0.0156" decimal. Set it up as high as you can in the machine. Loosen existing bit with provided hex wrench. | |||

# Clear out the memory of the Modela, by holding the both ""up" and "Down on the machine | |||

# Press on View button on the Model | |||

#Write correct xmin and ymin, depending on where the board is (e.g. 70 and 20) | |||

# Click on move to xmin,ymin | |||

#Go to the modela and lower the bit by pressing Down button but be careful, the leave at a least 5 mm above the lowest point.Be sure to not let the bit touch the surface. | |||

#Loosen the bit until it touches the board, but be careful and hold your finger at the bit while doing it. | |||

# Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board. | |||

#* Lower it slowly so the bit doesn't fall into the board and break. | |||

# Now that the bit is at surface level, tighten screw. | |||

#Click on make_path button | |||

#Click make_rml | |||

#Click send it! | |||

[[Image:Cam circuitcut1.png|thumb|350 px|right|Milling the circuit itself]] | |||

[[Image:Cam circuitcut2.png|thumb|350 px|right|Cutting out a circuit board]] | [[Image:Cam circuitcut2.png|thumb|350 px|right|Cutting out a circuit board]] | ||

# | == Cut out the board == | ||

# | # Press view button on the modela to move PCB forward. Be careful not to move board around in process. | ||

# | # Clean up any shavings from first mill. | ||

# | # Change bit to the 1/32 inch bit (0.0312 ) | ||

#* Be sure it doesn't fall out and break | |||

# | #Go to the computer again in Fab Modules, change from mill traces to cut out board (1/32) | ||

# | # Remove the "#" in front of the lines... | ||

#output= interior | |||

# Write # infront of output=traces | |||

#Click make_png | |||

#Click on make_path | |||

#Click on make_rml | |||

#Click move to xmin,ymin | |||

# Go to the modela and Press the view button place machine back in cutting mode and out of view mode. | |||

#lower the bit by pressing Down button but be careful, the leave at a least 5 mm above the lowest point.Be sure to not let the bit touch the surface. | |||

#Loosen the bit until it touches the board, but be careful and hold your finger at the bit while doing it. | |||

# Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board. | # Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board. | ||

* Lower it slowly so the bit doesn't fall into the board and break. | #* Lower it slowly so the bit doesn't fall into the board and break. | ||

# Now that the bit is at surface level, tighten screw. | # Now that the bit is at surface level, tighten screw. | ||

# | # Once bit is ready click on "send to machine" | ||

# Press the view button to enter view mode and remove your new PCB Board | |||

# Grab a coffee, it's going to be a long night. | |||

=== Finish === | |||

# Clean the shavings with a vacuum cleaner | |||

# Clean the circuit board with water and soap. This prevent future corrosion | |||

== If something goes wrong == | |||

If something goes wrong during the milling process press the view button on the machine. | |||

To clean out the memory of the machine press and hold the Up and Down button at the same time until the LED besides the view button stops blinking. | |||

If for some reason the above doesn't work (and it doesn't always-- especially with the modela print queue) you want to try to find other processes running on the computer and kill them. For example "cat" and "ttyS0" are the processes used for the Modela milling, so these are usually the processes that you need to kill. To find them and kill them, type the following into the terminal: | |||

ps -ef | grep ttyS0 | |||

(ps here represents "processes", and -e represents "everything", f represents full details on those processes, so this represents a global search on your computer for all the processes running related to the ttyS0 port) | |||

This will show you what process is running in ttyS0, which is the port the modela is connected to. When you see the process number you type at the prompt: | |||

kill -9 PID (PID=process ID number) | |||

Then check again to see if any "cat" process is running: | |||

ps -ef | grep cat | |||

(cat executes a command) | |||

If you see a cat process running kill that too: | |||

kill -9 PID | |||

Then reset the Modela by holding down the up and down buttons at the same time, and when the light stops blinking you're reset. | |||

[http://fab.cba.mit.edu/content/tools/software/cad_cam/ Cad/Cam info] | |||

== If you have the file.rml read y== | |||

If you have the file.rml ready and don't want to go to all the steps again you can open the terminal and write | |||

cat file.rml > /dev/ttyS0 | |||

| Line 86: | Line 111: | ||

A nice tutorial about this was written by people at the Delhi Fab Lab. It should be uploaded. | A nice tutorial about this was written by people at the Delhi Fab Lab. It should be uploaded. | ||

http://fablab.marcboon.com/pcb/ | * [http://fablab.marcboon.com/pcb/ http://fablab.marcboon.com/pcb/] | ||

* [http://www.fablab.is/w/images/8/8e/Circuits_descriptions.pdf Circuit descriptons. pdf] | |||

* [http://www.fablab.is/w/images/b/b0/Scotts_New_MIT_Hello_World_Circuits.pdf Scotts new Hello World Circuits description] | |||

[[Category:Category:Machine_Tutorials]] | |||

Latest revision as of 12:28, 14 August 2014

Step by Step

---

- Design the circuit board or select and download a cad file from the hello-world circuits section on the http://fab.cba.mit.edu/about/fab/ or from hello world electronics

- Stick a piece of the PCB copper plated stock onto the cutting plane at the 1,1 inch intersection on the grid.

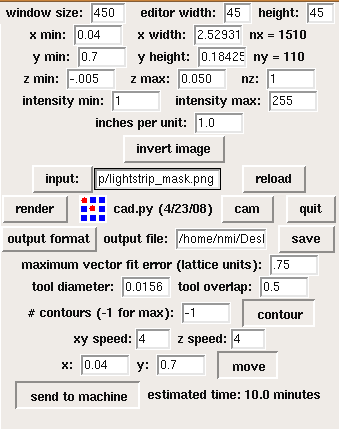

- Open fab Fab modules software by writing fab the terminal

- Click input and get the design file (.cad file) or a pre-designed png file.

Make the toolpath and mill a circuit

- Open Fab modules in a Linux Terminal by writing

fab

or click on the shortcut launcher in desktop.

- Selct from format: design.cad to process, Roland Modela .rml and then click make_cad_rml

- Click Load cad, select the right file.cad

- Select mill traces (1/64)

- Go to the text area and uncomment the "#" and remove the "#" in front of output="traces" (* The "#" symbol is a comment, which will ignore the line of the command after the sign.

)

- click on make_png

- change the offset to 8

- On the Modela go to "view mode" by pressing on the view button on the Modela

- Press view on the Modela machine

- Tape down copper board with double tape

- Put 1/64 inches bit in the modela, which is 0.0156" decimal. Set it up as high as you can in the machine. Loosen existing bit with provided hex wrench.

- Clear out the memory of the Modela, by holding the both ""up" and "Down on the machine

- Press on View button on the Model

- Write correct xmin and ymin, depending on where the board is (e.g. 70 and 20)

- Click on move to xmin,ymin

- Go to the modela and lower the bit by pressing Down button but be careful, the leave at a least 5 mm above the lowest point.Be sure to not let the bit touch the surface.

- Loosen the bit until it touches the board, but be careful and hold your finger at the bit while doing it.

- Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board.

- Lower it slowly so the bit doesn't fall into the board and break.

- Now that the bit is at surface level, tighten screw.

- Click on make_path button

- Click make_rml

- Click send it!

Cut out the board

- Press view button on the modela to move PCB forward. Be careful not to move board around in process.

- Clean up any shavings from first mill.

- Change bit to the 1/32 inch bit (0.0312 )

- Be sure it doesn't fall out and break

- Go to the computer again in Fab Modules, change from mill traces to cut out board (1/32)

- Remove the "#" in front of the lines...

#output= interior

- Write # infront of output=traces

- Click make_png

- Click on make_path

- Click on make_rml

- Click move to xmin,ymin

- Go to the modela and Press the view button place machine back in cutting mode and out of view mode.

- lower the bit by pressing Down button but be careful, the leave at a least 5 mm above the lowest point.Be sure to not let the bit touch the surface.

- Loosen the bit until it touches the board, but be careful and hold your finger at the bit while doing it.

- Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board.

- Lower it slowly so the bit doesn't fall into the board and break.

- Now that the bit is at surface level, tighten screw.

- Once bit is ready click on "send to machine"

- Press the view button to enter view mode and remove your new PCB Board

- Grab a coffee, it's going to be a long night.

Finish

- Clean the shavings with a vacuum cleaner

- Clean the circuit board with water and soap. This prevent future corrosion

If something goes wrong

If something goes wrong during the milling process press the view button on the machine. To clean out the memory of the machine press and hold the Up and Down button at the same time until the LED besides the view button stops blinking.

If for some reason the above doesn't work (and it doesn't always-- especially with the modela print queue) you want to try to find other processes running on the computer and kill them. For example "cat" and "ttyS0" are the processes used for the Modela milling, so these are usually the processes that you need to kill. To find them and kill them, type the following into the terminal:

ps -ef | grep ttyS0

(ps here represents "processes", and -e represents "everything", f represents full details on those processes, so this represents a global search on your computer for all the processes running related to the ttyS0 port)

This will show you what process is running in ttyS0, which is the port the modela is connected to. When you see the process number you type at the prompt:

kill -9 PID (PID=process ID number)

Then check again to see if any "cat" process is running:

ps -ef | grep cat

(cat executes a command)

If you see a cat process running kill that too:

kill -9 PID

Then reset the Modela by holding down the up and down buttons at the same time, and when the light stops blinking you're reset.

If you have the file.rml read y

If you have the file.rml ready and don't want to go to all the steps again you can open the terminal and write

cat file.rml > /dev/ttyS0

Using Eagle

A nice tutorial about this was written by people at the Delhi Fab Lab. It should be uploaded.