Jan Gunster: Difference between revisions

| Line 25: | Line 25: | ||

== Fab Academy == | == Fab Academy == | ||

The Fab Academy is an international class hosted by Neil Gerschenfield at M.I.T. | The Fab Academy is an international class hosted by Neil Gerschenfield at M.I.T. | ||

---- | ---- | ||

Revision as of 13:17, 3 November 2009

Overview

Jan Gunster is a Student of Concept Design from The Netherlands and currently on a 4 month internship at the FabLab in Iceland.

Projects

T-shirt

A project to get local youth more interested

3d Rotate

The 3d rotate tool was a concept that used simple parts to create the illusion of a 3d scan.

Improving FabLab's identity

Together with Frosti I made some improvements in and around the FabLab to give it more of an identity and overall a more cohesive feel. For this I used the Vinyl cutter and lots and lots of sticker material.

Fab Academy

The Fab Academy is an international class hosted by Neil Gerschenfield at M.I.T.

Assignment one

I entered the Fab Academy late, so the first assignment I started working on was making press fits. I produced 3 different designs, each with its own problems and challenges.

Jet Fighter

For this press fit, shaped like a jet fighter, I drew inspiration upon the little toy airplanes I had a kid. Where the hull is one piece, and the wings a second piece that fold into each other at a 90 degree angle. My first design was like this. Straightforward and simple. Then I moved on to a design abit more complex. In the second design added tail wings. Here, however, I got some measurements wrong which I fixed in the third version. V.4 was an improvement on the overall design and shape. I also added a landing gear and bombs under the wings. In this version I also added decals. In my 5th and final version I perfected this design.

Eiffel Tower

The Eiffel Tower was by far my most challenging design. The idea was simple, four legs each made of one piece, connected at 90 degree angles with two platforms 45 degree angle. The execution was harder, however. The problem was mostly in the material choice. Wood. This proved far too fragile and I had to redesign the entire Eiffel Tower several Times. It kept burning up because the framework was too small. In my fourth and final redesign I opted to increase the size by a factor of two and make the whole thing out of cardboard. This version too proved a failure as the platforms were to small and the legs had a shape that didn't match up. In my fifth and final version I fixed this. I was glad to be done.

Toys

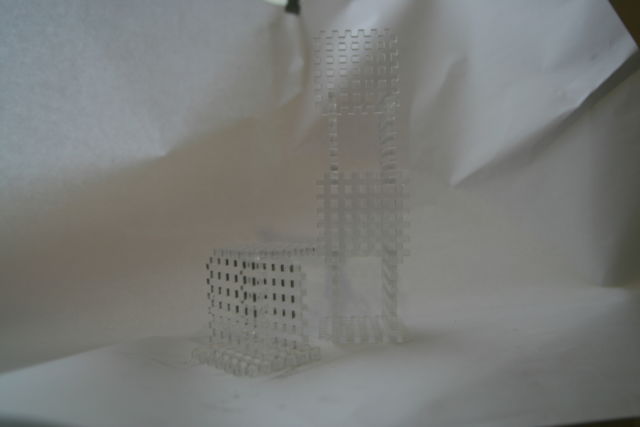

Not happy with my previous designs I opted for a final design that would incorporate everything I had learned. I wanted to make something simple - but varied and complex. I drew inspiration from the Lego's I played with as a kid, as they are essentially press-fits. I wanted to make something similar. One simple design that one could build anything with. This is close to the general philosophy of the FabLab and I liked that. I made squares from cardboard that are similar to your standard press-fit. Only with more gaps. This was a faulty design however. It was limited in building potential and prone to break. So I changed it to Plexiglas, which is harder and stronger. I also made the parts like a grate, with many holes. This version was successful and I am very happy with the result. It would be nice to get some kids to play with this. As a final note I would like to add that I have learned that plexiglass is far from the best material for this, its not flexible and prone to breaking.

Summary

General problems I ran into: Choosing the wrong material, disconnects within software (illustrator /inkscape), making designs too small /too big. The machine not doing what I wanted. Learned: To operate, calibrate and clean the Laser Cutter. Work in the Inkscape software package. Create and Design my own press-fits.

Assignment two

The second assignment was about electronics. I'm not that good at making electronics so this was great learning.

Circuit Board

It all started with milling out a would-be circuit board on the milling machine. The second try got it right. For the first try I put the drill too far into the machine, so it couldn't drill deep enough to make a good board.

The second part was actually soldering the parts on. This is where the trouble started - I have shaky hands. After about an hour and a half of soldering on my first board I gave up. I had messed up three parts and the board was irrepairable. Part due to my lack of experience in soldering. Sadly, I had to drill out a new circuit board, and decided to get a good night's rest and try again. This proved to be a good decision and the second time I got it right. I made a circuit board!

The third part is programming the circuit board. I quickly ran into problems as I used a 3.3V regulator where I should have used a 5V regulator. I made quick work of it by replacing it quickly and efficiently (unlike other endeavors on said board).