Making serial cables: Difference between revisions

No edit summary |

No edit summary |

||

| Line 27: | Line 27: | ||

Important: Check if the wire exits the connector in the same direction that it exits the board. | Important: Check if the wire exits the connector in the same direction that it exits the board. | ||

Important: Leave a 3 cm tip on the other end of the connector. It could be useful to troubleshooting. | Important: Leave a 3 cm tip on the other end of the connector. It could be useful to troubleshooting. | ||

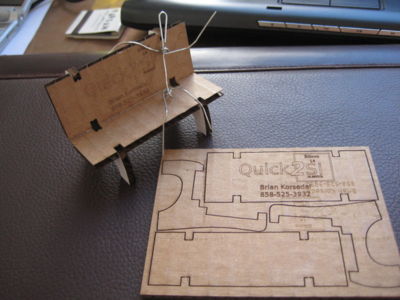

[[Image:Example.jpg]] | [[Image:Example.jpg|thumb|400 px|This is the text under]] | ||

*Place the back shell and do a lot of pressure. From my little experience we need to do a lot of pressure, we used the panavise existing in the lab to "pressurize", but be carefull so that you don't brake the connector! | *Place the back shell and do a lot of pressure. From my little experience we need to do a lot of pressure, we used the panavise existing in the lab to "pressurize", but be carefull so that you don't brake the connector! | ||

Revision as of 23:36, 15 January 2010

The purpose of this tutorial is to clarify the assembly of the DB9 serial to "5 Pin MTA connector" cable used in FabLab.

Materials:

- One female DB9 serial connector

- One 5 Pin MTA connector

- Flat cable with 5 wires

- Wire Cutter

- Vice!

First thing is to know what connect to!

Thanks to Jan we have these beautiful drawings of the connectors

http://www.fablab.is/w/index.php/Image:Wires.png

And this beautiful drawing of the connection.

http://www.fablab.is/w/index.php/Image:Wires2.png

5 Pin MTA Connector

Note: Start by the 5 pin MTA connector because it is easier to do this with the wire order of the flat cable.

- Put the wires over the blades corresponding to the pins we want to connect to and press them a little bit so that they hold.

Important: Check if the wire exits the connector in the same direction that it exits the board. Important: Leave a 3 cm tip on the other end of the connector. It could be useful to troubleshooting.

- Place the back shell and do a lot of pressure. From my little experience we need to do a lot of pressure, we used the panavise existing in the lab to "pressurize", but be carefull so that you don't brake the connector!

==DB9 connector==.

- Spread the wires in one tip of the flat cable for about five centimeters.

- Put the wires over the blades corresponding to the pins we want to connect to and press them a little bit so that they hold.

- Place the back shell and do a lot of pressure until you hear a click.

- Place the strain relief over back shell the connector and do some pressure until you hear a click.

Important: Check if the wire exits the connector in the same direction that it exits the board. Important: Leave a 3 cm tip on the other end of the connector. It could be useful to troubleshooting.

The cable is done!

Know one must check if it is well connected.

Troubleshooting:

Place a male connector to the female db9 to access easily to the pins. Also place a male connector in the MT5 connector for the same reason. Then with a multimeter as an Ohmmeter, check for continuity in the corresponding pins.

If you don't have continuity it can be one of two things.

- Misplacement of the wires in the pins. Check the other pins were you were not supposed to have any continuity.

- Not enough pressure in the back shell of the connector and therefor no contact. To check that take a little bit of isolation of the excess cable left before, and measure continuity between this tip and the pin in the back of the auxiliary male connector. If you don't have continuity press a little harder and check again.