How to use the Modela: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Image:Modela.jpg|thumb|300px|right|Roland Modela can be used to mill circuit boards.]] | [[Image:Modela.jpg|thumb|300px|right|Roland Modela can be used to mill circuit boards.]] | ||

== Step by | === Step by Step === | ||

---- | |||

[[Image:Modela_buttons.jpg|thumb|200px|right|Modela buttons, from top: Power, View, Up, Down]] | [[Image:Modela_buttons.jpg|thumb|200px|right|Modela buttons, from top: Power, View, Up, Down]] | ||

# Design the circuit board | # Design the circuit board or select and download a cad file from the hello-world circuits section on the http://fab.cba.mit.edu/about/fab/ or from [[hello world electronics]] | ||

# Stick a piece of PCB stock onto the cutting plane | # Stick a piece of the PCB copper plated stock onto the cutting plane at the 1,1 inch intersection on the grid. | ||

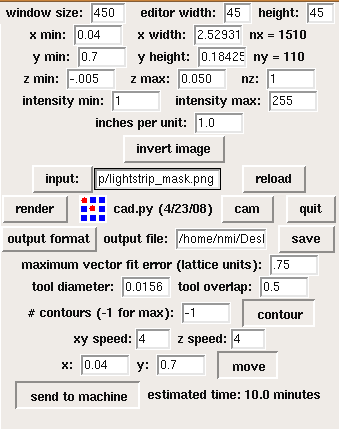

# Open Cad.py | # Open Cad.py software | ||

# Click input and get a | # Click input and get the design file (.cad file) or a pre-designed png file. | ||

=== Make the toolpath === | === Make the toolpath === | ||

| Line 19: | Line 22: | ||

# Set contours to -1 (meaning infinite) | # Set contours to -1 (meaning infinite) | ||

# Click Contour | # Click Contour | ||

*This will set the toolpath for the file | |||

This will | |||

[[Image:Cam circuitcut1.png|thumb|350 px|right|Milling the circuit itself]] | [[Image:Cam circuitcut1.png|thumb|350 px|right|Milling the circuit itself]] | ||

[[Image:Cam circuitcut2.png|thumb|350 px|right|Cutting out a circuit board]] | [[Image:Cam circuitcut2.png|thumb|350 px|right|Cutting out a circuit board]] | ||

| Line 45: | Line 45: | ||

=== Cut out the Board === | === Cut out the Board from the PCB === | ||

# Press view button to move PCB forward. Be careful not to move board around in process. | |||

# Clean up any shavings from first mill. | |||

# Change bit to the 1/32 inch bit (0.0312 ) | |||

#* Be sure it doesn't fall out and break | |||

# Open back up cad.py software | |||

# Change tool diameter to 0.0312 | |||

# Change number of contours from -1 to 1 | |||

# Change xy speed: to 0.5 and z speed: to 0.5 | |||

# Remove the "#" in front of the lines... | |||

#cad.function = pcb.interior | |||

#z = -.065 | |||

# Búðu til skurðarbrautina fyrir rafrásina; notaðu möskvann sem á að skera eftir. Gættu þess að gera ráð fyrir 1/32" tönn. | # Búðu til skurðarbrautina fyrir rafrásina; notaðu möskvann sem á að skera eftir. Gættu þess að gera ráð fyrir 1/32" tönn. | ||

Revision as of 21:49, 24 June 2009

Step by Step

- Design the circuit board or select and download a cad file from the hello-world circuits section on the http://fab.cba.mit.edu/about/fab/ or from hello world electronics

- Stick a piece of the PCB copper plated stock onto the cutting plane at the 1,1 inch intersection on the grid.

- Open Cad.py software

- Click input and get the design file (.cad file) or a pre-designed png file.

Make the toolpath

- Make the toolpath for the circuit. Use a 1/64" tool, which is 0.0156" decimal.

- Click CAM

- Click Output format and choose .rml (Modela)

- If you're using a circuit board written in Python, you'll find a line near the bottom saying "#dpi = 500 ".

- Move the ("#") sign to the line above which is "dpi=200

- The "#" symbol is a comment, which will ignore the line of the command after the sign.

- Use "dpi = 200 # low resolution for previewing" for previewing toolpath contour

- Use "dpi = 500 # high resolution for machining" actual rendering and sending to Modela (takes longer to render)

- Set contours to -1 (meaning infinite)

- Click Contour

- This will set the toolpath for the file

Milling a circuit

- Go to "view mode" by click on the view button on the Modela

- Tape down copper board at o,o position ( 1 inch x 1 inch from bottom left corner)

- Put 1/64 inches bit in the modela, which is 0.0156" decimal. Set it up as high as you can in the machine. Loosen existing bit with provided allen wrench.

- Clear out the memory of the Modela, by holding the both ""up" and "Down on the machine

- Open file in cad...follow instructions "Make a toolpath"

- Set the x,y axis starting point on the project to 1, 1 on the control panel in cad and then click "move"

- Lower bit close to the corner (1,1) by pressing the "Down" button. Be sure to not let the bit touch the surface.

- Loosen the hex screw that holds the bit and lower it until it touches the top surface of the board.

- Lower it slowly so the bit doesn't fall into the board and break.

- Now that the bit is at surface level, tighten screw.

- Open cad again and then send to machine.

- Grab a coffee, it's going to be a long night.

Cut out the Board from the PCB

- Press view button to move PCB forward. Be careful not to move board around in process.

- Clean up any shavings from first mill.

- Change bit to the 1/32 inch bit (0.0312 )

- Be sure it doesn't fall out and break

- Open back up cad.py software

- Change tool diameter to 0.0312

- Change number of contours from -1 to 1

- Change xy speed: to 0.5 and z speed: to 0.5

- Remove the "#" in front of the lines...

#cad.function = pcb.interior #z = -.065

- Búðu til skurðarbrautina fyrir rafrásina; notaðu möskvann sem á að skera eftir. Gættu þess að gera ráð fyrir 1/32" tönn.

- Settu 1/32" fræsitönn í fræsivélina,

- Fyllið inn í hugbúnaðinum í reitinn við Tool diameter: 0.0312

- Stillið Contours í hugbúnaðnum á 1.

- xy speed 0.5 og z speed 0.5.

- Í textaritlinum skal fjarlægja # fyrir framan cad.function = frame og # fyrir framan z = -.065skal fjarlægja "#" þar sem stendur:

#cad.function = pcb.interior #z = -.065

- Smellið á Contour í hugbúnaðnum

- Farðu úr View mode með því að smella á View takkann á fræsivélinni og stilltu núllpunkt á X og Y ás úr hugbúnaðinum með því að smella á Move. Notaðu nákvæmlega sama núllpunkt og áður!

- Haltu Down takkanum inni þar til að fræsihausinn færist niður að plötunni, ekki láta hana snerta

- Losaðu skrúfuna sem heldur fræsitönninni þannig að tönninn detti niður og snerti plötuna.

- Prófaðu að lyfta henni og sleppa til að vera viss um að ekkert sé fyrir

- Hertu skrúfuna fyrir fræsitönnina

- Sendu verkefnið á tækið.

Frágangur

- Taka agnir i burtu med t.d. ryksugu

- hreinsa rafrásarbrettið með því að skola það með vatni og sápu til þess að rásin tærist ekki með tímanum.

Ef eitthvað fer úrskeiðis

Ef eitthvað kemur upp á við fræsingu er hægt að smella á View takkann á fræsivélinni.

Til þess að hreinsa úr minni fræsivélarinnar er UP og DOWN tökkunum haldið inni í 5-6 sekúndur, halda tökkunum inni þar til Led ljós er hættir að blikka hjá VIEW takkanum..

Ef verkefni er sem hefur verið sent á úr cad.py er stöðvað þarf að slökkva á forritinu og byrja upp á nýtt. Þetta er t.d. hægt að gera með því að fara í Terminal í Linux og skrifa killall -9 python

Using Eagle

A nice tutorial about this was written by people at the Delhi Fab Lab. It should be uploaded.